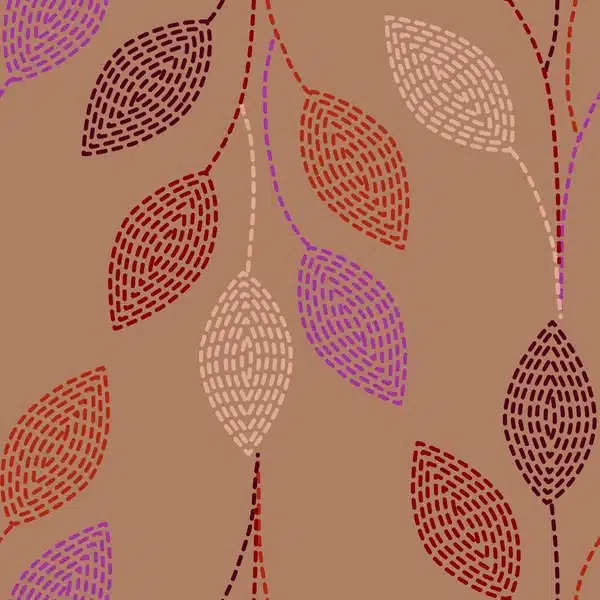

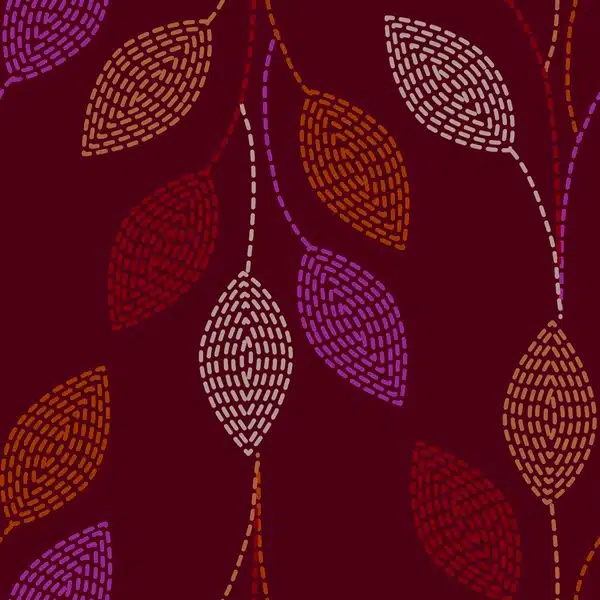

Leaf

Leaf fabrics embody the essence of nature with intricate patterns resembling woven and stitched leaves. Ideal for healthcare settings, the organic designs create a serene and tranquil atmosphere, promoting calm and well-being.

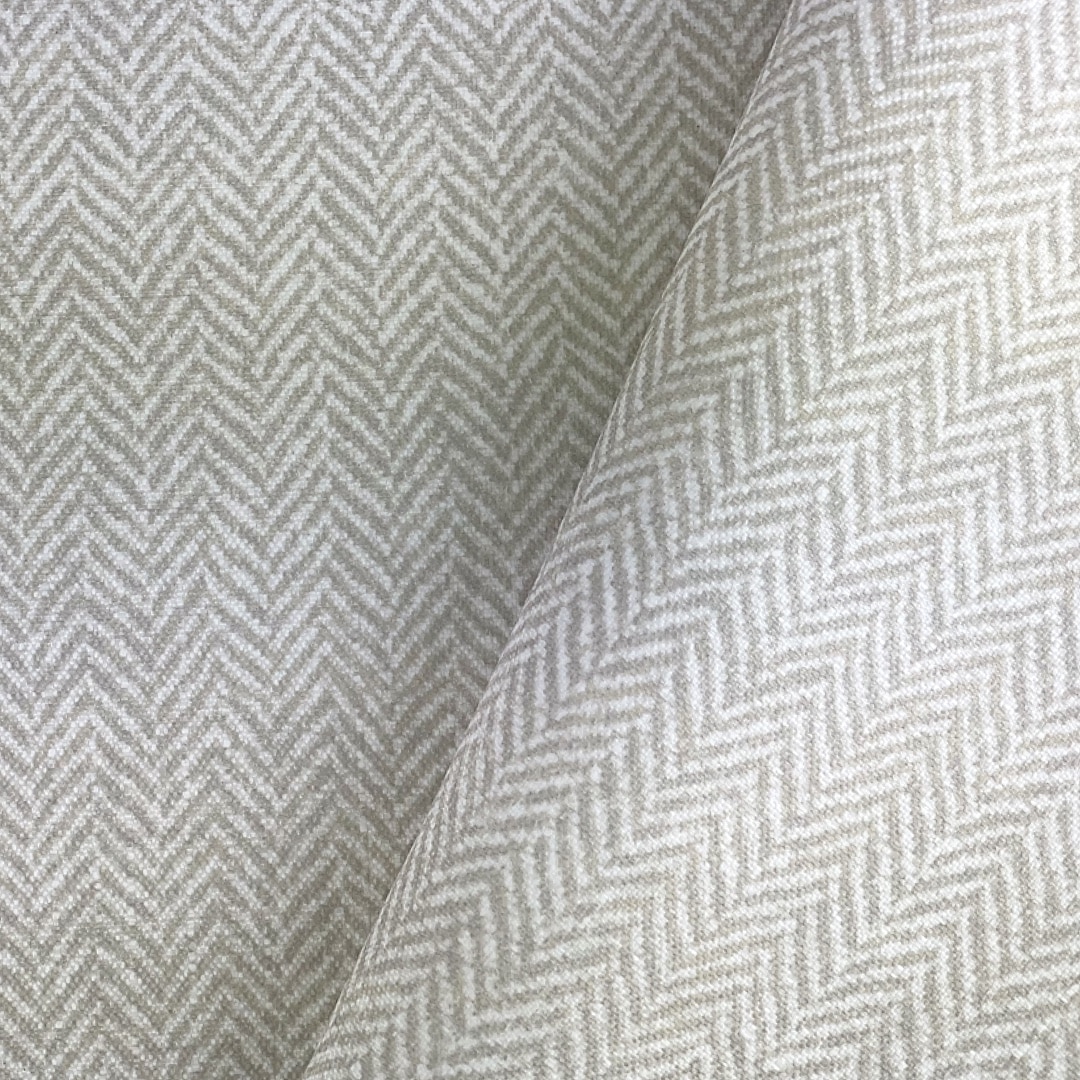

Leaf - Feather Grey

Leaf - Feather Grey

Colourways

12 ColoursFull Specifications

composition & weight

abrasion resistance

Martindale Abrasion Method AS 2001.2.25 (12kPa)

No Significant wear after completion of abrasion test (rubs)

finishes

Surface finish – Stain repellent Fluorocarbon C6 technology.

Kinder to the environment – PFOA/PFOS free.

Back coating (Waterproof) – Water based Polyurethane coating, heavy metal free

f.r standards

Tested to Australian standards AS 1530.3

Spread of Flame Index : 0

Smoke Developed Index : 5

I.M.O Standards A.652 (16 )

AS/NZS 3837

*Fire test certificates available upon request

anti-bacterial

Treated for bacterial protection resistant to bacteria growth – AATCC 100-2102

bleach cleanable

Tested to Australian standards AS 2001.4.11

Class 4-5 – No change of colour

Acceptable bleach cleaning – 1 part bleach 10 parts water & rinse thoroughly.

High concentration of bleach or long term exposure to bleach not recommended.

colourfastness to light

Tested to Australian standards

AS 2001.4.21-2006

Final Rating 4

Fusion is suitable for indoor use only.

Protect from direct sunlight.

environmental

Fusion fabrics are free of potentially harmful levels of Formaldehyde, heavy metals,

PFOA, PFOS, Phthalates and Phenols.

Fusion fabrics can be recycled.

performance properties

Water Resistance Hydrostatic Head

ATCC 127-2008 – 120cms

Tear strength

ASTM D2261-1 (Tongue Single Rip)

Length 180N Width 418 N

Tensile strength

ASTM D5034-2009 (Grab Method) –

Mean breaking force 2000 N

Seam slippage

ASTM D4034-92

No seam slippage Warp 228N, Weft 223N

Pilling resistance ASTM D3511-2005 – No pilling

*Test certificates available upon request.

stain resistance

ISO 105 A03Water Based Removal of – After 24 hours

Blood (Artificial) 5

Urine (Artificial) 5

Betadine 5

Iodine 5

Tomato sauce 5

Sun tan Lotion 4-5

• Class 5 – complete removal

• Class 4 – Good removal

• Class 1 – No removal

care & maintenance

Regular maintenance – Vacuum fabric regularly to remove crumbs, dust and dirt to avoid build up.

Spills – Soak up spills as quickly as possible using dry absorbent cloth.

Stains – Most stains can be cleaned using a damp cloth. For persistent stains use a warm soapy

water solution. Moderate scrubbing with a soft bristle brush and soapy solution will help loosen

soiling from the fabric surface. It is very important to remove all soap residue with clean water.

Fusion can also be cleaned with a bleach solution (1 part bleach 10 parts water) rinse all residue.

Do not use solvent based cleaners. Failure to follow cleaning instructions may permanently stain

and reduce the life of the fabric.

usage

Waterproof upholstery fabrics, suitable for Heavy Commercial and Healthcare applications.